LLL317R71H103MD01K 데이터 시트보기 (PDF) - Unspecified

부품명

상세내역

일치하는 목록

LLL317R71H103MD01K Datasheet PDF : 296 Pages

| |||

!Note • Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

C02E.pdf

Nov.27,2017

!Caution

Continued from the preceding page.

8. Assembly

1. Handling

If a board mounted with capacitors is held with one hand,

the board may bend. Firmly hold the edges of the board

with both hands when handling.

If a board mounted with capacitors is dropped, cracks

may occur in the capacitors.

Do not use dropped boards, as there is a possibility that

the quality of the capacitors may be impaired.

2. Attachment of Other Components

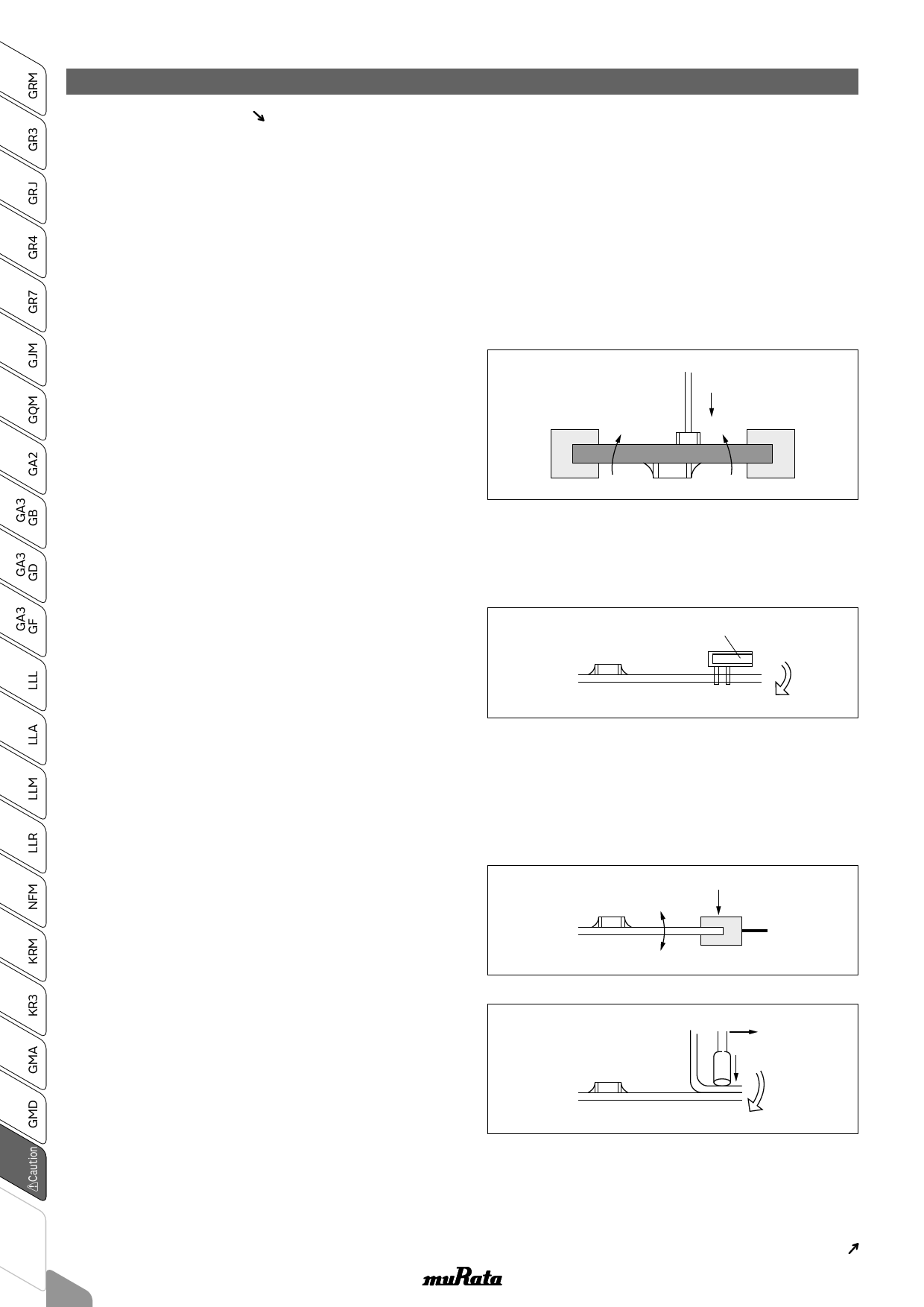

2-1. Mounting of Other Components

Pay attention to the following items, when mounting

other components on the back side of the board

a er capacitors have been mounted on the opposite

side.

When the bottom dead point of the suction nozzle is

set too low, board deflection stress may be applied

to the capacitors on the back side (bottom side), and

cracks may occur in the capacitors.

· A er the board is straightened, set the bottom

dead point of the nozzle on the upper surface of the

board.

· Periodically check and adjust the bottom dead point.

2-2. Inserting Components with Leads into Boards

When inserting components (transformers, IC, etc.)

into boards, bending the board may cause cracks in

the capacitors or cracks in the solder.

Pay attention to the following.

· Increase the size of the holes to insert the leads, to

reduce the stress on the board during insertion.

· Fix the board with support pins or a dedicated jig

before insertion.

· Support below the board so that the board does not

bend. When using support pins on the board,

periodically confirm that there is no di erence in

the height of each support pin.

2-3. Attaching/Removing Sockets and/or Connectors

Insertion and removal of sockets and connectors,

etc., might cause the board to bend. Please insure

that the board does not warp during insertion and

removal of sockets and connectors, etc., or the

bending may damage mounted components on the

board.

2-4. Tightening Screws

The board may be bent, when tightening screws, etc.

during the attachment of the board to a shield or

chassis.

Pay attention to the following items before

performing the work.

· Plan the work to prevent the board from bending.

· Use a torque screwdriver, to prevent

over-tightening of the screws.

· The board may bend a er mounting by reflow

soldering, etc. Please note, as stress may be applied

to the chips by forcibly flattening the board when

tightening the screws.

280

Suction Nozzle

Component with Leads

Socket

Screwdriver

Continued on the following page.