LLL317R71H103MD01K 데이터 시트보기 (PDF) - Unspecified

부품명

상세내역

일치하는 목록

LLL317R71H103MD01K Datasheet PDF : 296 Pages

| |||

!Note • Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

C02E.pdf

Nov.27,2017

Notice

Continued from the preceding page.

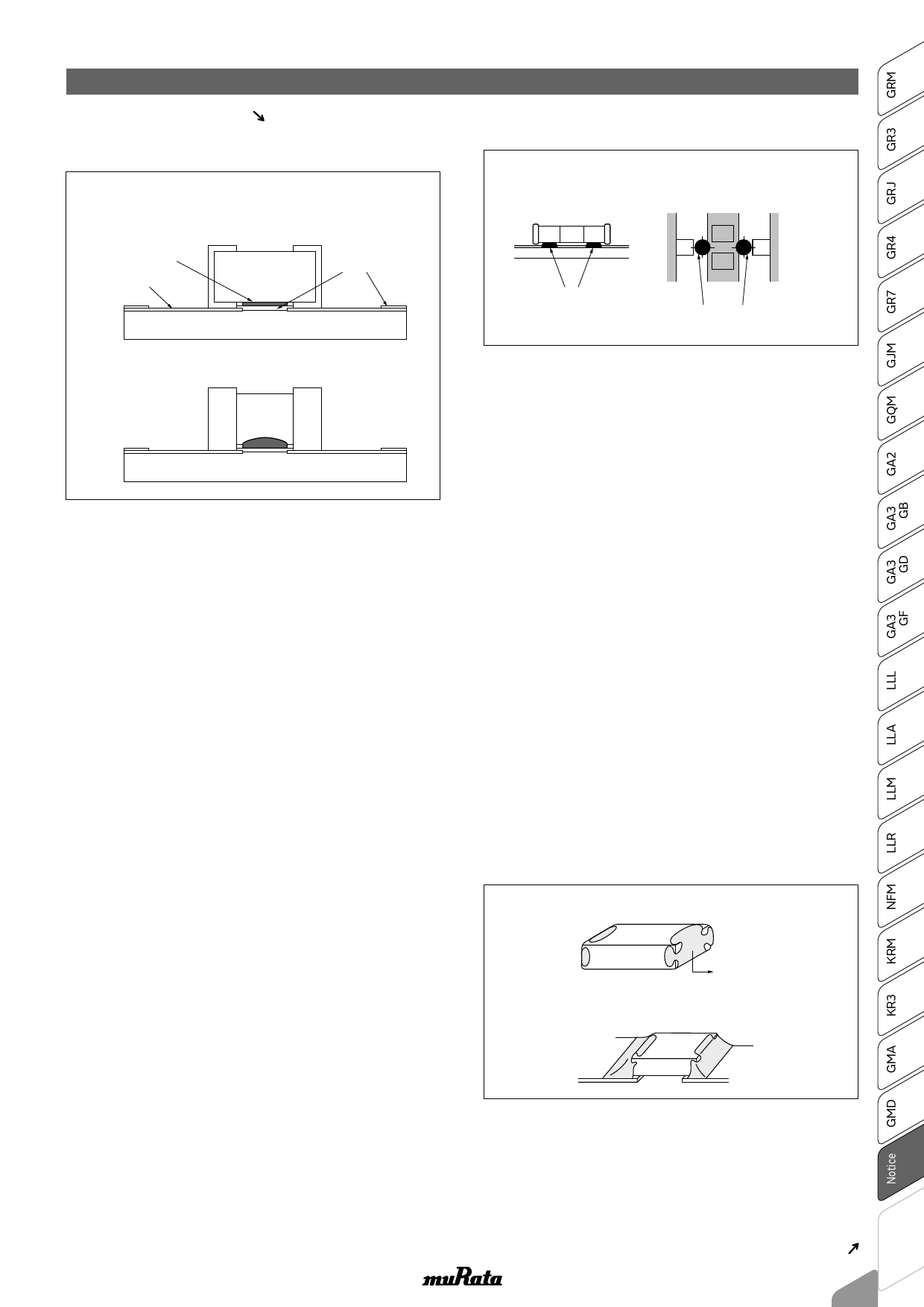

(2) Use the following illustration as a guide to the

amount of adhesive to apply.

[Sizes: 0603(1608M) / 0805(2012M) / 1206(3216M)]

Cross Sectional View

Adhesive

Land

Resist

Board

<Applicable to NFM Series>

[Sizes: 1205(3212M) / 1206(3216M) / 1806(4516M)]

Bonding agent

Coating position of

bonding agent

Side View

3. Adhesive Curing

1. Insu cient curing of the adhesive can cause chips to

disconnect during flow soldering and causes deterioration

in the insulation resistance between the terminations due

to moisture absorption.

Control curing temperature and time in order to prevent

insu cient hardening.

4. Flux for Flow Soldering

1. An excessive amount of flux generates a large quantity of

flux gas, which can cause a deterioration of solderability,

so apply flux thinly and evenly throughout. (A foaming

system is generally used for flow soldering.)

2. Flux containing too high a percentage of halide may cause

corrosion of the terminations unless there is su cient

cleaning. Use flux with a halide content of 0.1% max.

3. Strong acidic flux can corrode the capacitor and degrade

its performance.

Please check the quality of capacitor a er mounting.

5. Flow Soldering

o Set temperature and time to ensure that leaching of the

terminations does not exceed 25% of the chip end area

as a single chip (full length of the edge A-B-C-D shown at

right) and 25% of the length A-B shown as mounted on

substrate.

[As a Single Chip]

A

B

D

C

Termination (Outer Electrode)

[As Mounted on Substrate]

B

A

6. Reflow Soldering

The flux in the solder paste contains halogen-based

substances and organic acids as activators.

Strong acidic flux can corrode the capacitor and degrade

its performance.

Please check the quality a er mounting, please use.

Continued on the following page.

289