CS5231-3 데이터 시트보기 (PDF) - Cherry semiconductor

부품명

상세내역

일치하는 목록

CS5231-3 Datasheet PDF : 11 Pages

| |||

Application Information: continued

cally 25°C and allows the IC to recover from a thermal

fault without the need for an external reset signal. The

monitoring circuitry is located near the composite PNP-

NPN output transistor, since this transistor is responsible

for most of the on-chip power dissipation. The combina-

tion of current limit and thermal shutdown will protect the

IC from nearly any fault condition.

Reverse Current Protection

During normal system operation, the auxiliary drive cir-

cuitry will maintain voltage on the VOUT pin when VIN is

absent. IC reliability and system efficiency are improved

by limiting the amount of reverse current that flows from

VOUT to ground and from VOUT to VIN. Current flows from

VOUT to ground through the feedback resistor divider that

sets up the output voltage. This resistor can range in value

from 6kΩ to about 10kΩ, and roughly 500µA will flow in

the typical case. Current flow from VOUT to VIN will be

limited to leakage current after the IC shuts down. On-chip

RC time constants are such that the output transistor

should be turned off well before VIN drops below the VOUT

voltage.

and heatsink-to-air thermal resistance (θSA). The resulting

equation for junction-to-air thermal resistance is

θJA = θJC + θCS + θSA

The value of θJC for the CS5231-3 is provided in the

Packaging Information section of this data sheet. θCS can

be considered zero, since heat is conducted out of the

package by the IC leads and the tab of the D2PAK package,

and since the IC leads and tab are soldered directly to the

PC board.

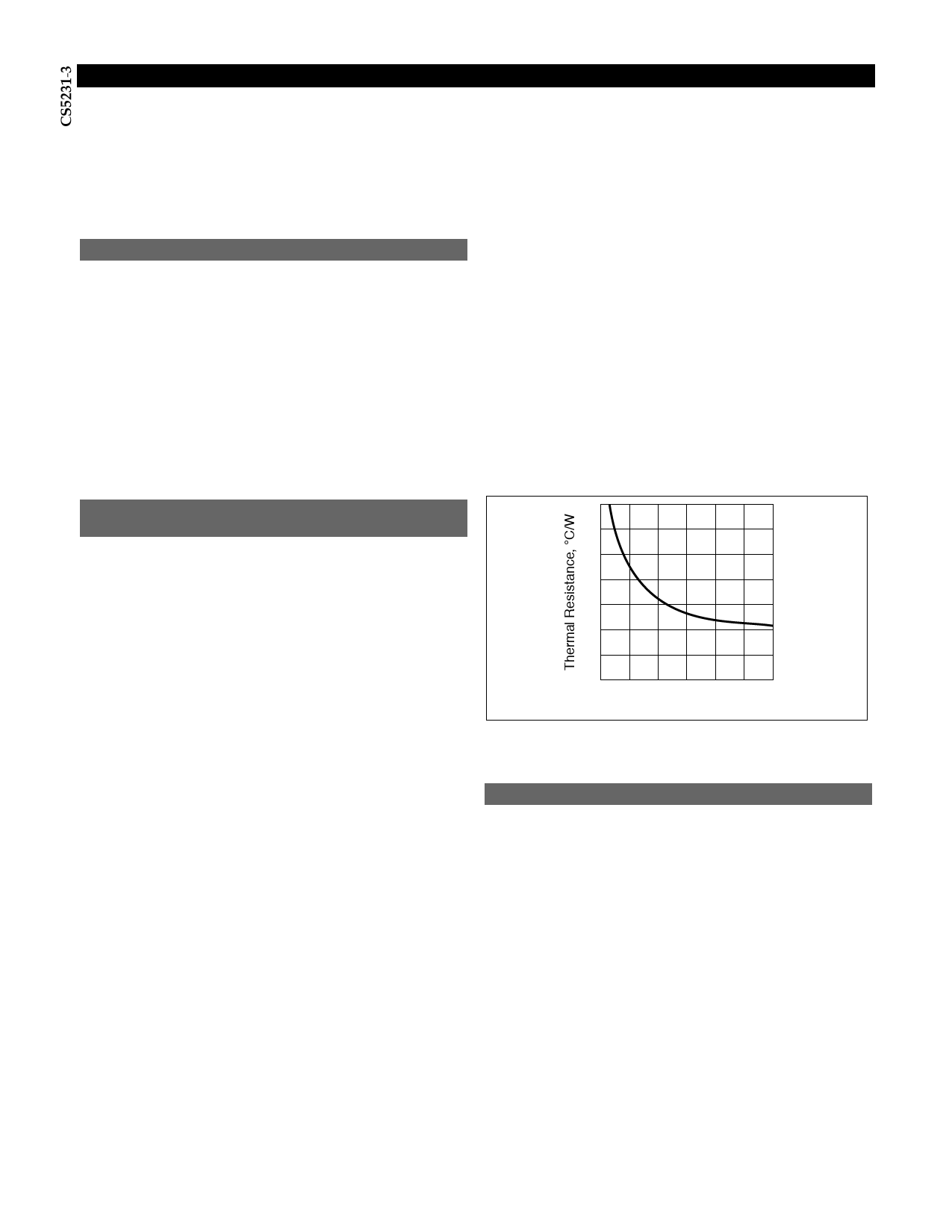

Modification of θSA is the primary means of thermal man-

agement. For surface mount components, this means mod-

ifying the amount of trace metal that connects to the IC.

The thermal capacity of PC board traces is dependent on

how much copper area is used, whether or not the IC is in

direct contact with the metal, whether or not the metal sur-

face is coated with some type of sealant, and whether or

not there is airflow across the PC board. The chart provid-

ed below shows heatsinking capability of a square, single

sided copper PC board trace. The area is given in square

millimeters. It is assumed there is no airflow across the PC

board.

Calculating Power Dissipation and

Heatsink Requirements

Most linear regulators operate under conditions that result

in high on-chip power dissipation. This results in high

junction temperatures. Since the IC has a thermal shut-

down feature, ensuring the regulator will operate correctly

under normal conditions is an important design considera-

tion. Some heatsinking will usually be required.

Thermal characteristics of an IC depend on four parame-

ters: ambient temperature (TA in °C), power dissipation

(PD in watts), thermal resistance from the die to the ambi-

ent air (θJA in °C per watt) and junction temperature (TJ in

°C). The maximum junction temperature is calculated from

the formula below:

TJ(MAX) = TA(MAX) + (θJA) (PD(MAX))

Maximum ambient temperature and power dissipation are

determined by the design, while θJA is dependent on the

package manufacturer. The maximum junction tempera-

ture for operation of the CS5231-3 within specification is

150°C. The maximum power dissipation of a linear regula-

tor is given as

PD(MAX) = (Vin(MAX) − VOUT(MIN)) (ILOAD(MAX))

+ (VIN (MAX)) (IGnd(MAX))

where IGnd(MAX) is the IC bias current.

It is possible to change the effective value of θJA by adding

a heatsink to the design. A heatsink serves in some manner

to raise the effective area of the package, thus improving

the flow of heat from the package into the surrounding air.

Each material in the path of heat flow has its own charac-

teristic thermal resistance, all measured in °C per watt. The

thermal resistances are summed to determine the total

thermal resistance between the die junction and air. There

are three components of interest: junction-to-case thermal

resistance (θJC), case-to-heatsink thermal resistance (θCS)

70

60

50

40

30

20

10

00

2000

4000

6000

PC Board Trace Area (mm2)

Figure 5: Thermal Resistance Capability of Copper PC Board Metal

Traces

Typical D2PAK PC Board Heatsink Design

A typical design of the PC board surface area needed for

the D2PAK package is shown below. Calculations were

made assuming VIN(MAX) =5.25V, VOUT(MIN) = 3.266V,

IOUT(MAX) = 500mA, IGnd(MAX) = 5mA and TA = 70°C.

PD = (5.25V − 3.266V) (0.5A) + (5.25V) (0.005A) = 1018mW

Maximum temperature rise ∆T = TJ(MAX) − TA =

150°C − 70°C = 80°C.

θJA (worst case) = ∆T/PD = 80°C/1.018W = 78.56°C/W

First, we determine the need for heatsinking. If we assume

the maximum θJA = 50°C/W for the D2PAK, the maximum

temperature rise is found to be

∆T = (PD) (θJA) = (1.018W) (50°C/W) = 50.9°C

This is less than the maximum specified operating junction

temperature of 125°C, and no heatsinking is required.

Since the D2PAK has a large tab, mounting this part to the

8