CS8164 데이터 시트보기 (PDF) - Cherry semiconductor

부품명

상세내역

일치하는 목록

CS8164 Datasheet PDF : 8 Pages

| |||

Application Notes: continued

Step 3: Increase the ESR of the capacitor from zero using

the decade box and vary the load current until oscillations

appear. Record the values of load current and ESR that

cause the greatest oscillation. This represents the worst

case load conditions for the output at low temperature.

Step 4: Maintain the worst case load conditions set in step

3 and vary the input voltage until the oscillations increase.

This point represents the worst case input voltage condi-

tions.

Step 5: If the capacitor is adequate, repeat steps 3 and 4

with the next smaller valued capacitor. A smaller capacitor

will usually cost less and occupy less board space. If the

output oscillates within the range of expected operating

conditions, repeat steps 3 and 4 with the next larger stan-

dard capacitor value.

Step 6: Test the load transient response by switching in

various loads at several frequencies to simulate its real

working environment. Vary the ESR to reduce ringing.

Step 7: Remove the unit from the environmental chamber

and heat the IC with a heat gun. Vary the load current as

instructed in step 5 to test for any oscillations.

Once the minimum capacitor value with the maximum

ESR is found for each output, a safety factor should be

added to allow for the tolerance of the capacitor and any

variations in regulator performance. Most good quality

aluminum electrolytic capacitors have a tolerance of +/-

20% so the minimum value found should be increased by

at least 50% to allow for this tolerance plus the variation

which will occur at low temperatures. The ESR of the

capacitors should be less than 50% of the maximum allow-

able ESR found in step 3 above.

Repeat steps 1 through 7 with the capacitor on the other

output, C3.

IIN

VIN

Smart

Regulator

}Control

Features

IQ

IOUT1

IOUT2

VOUT1

VOUT2

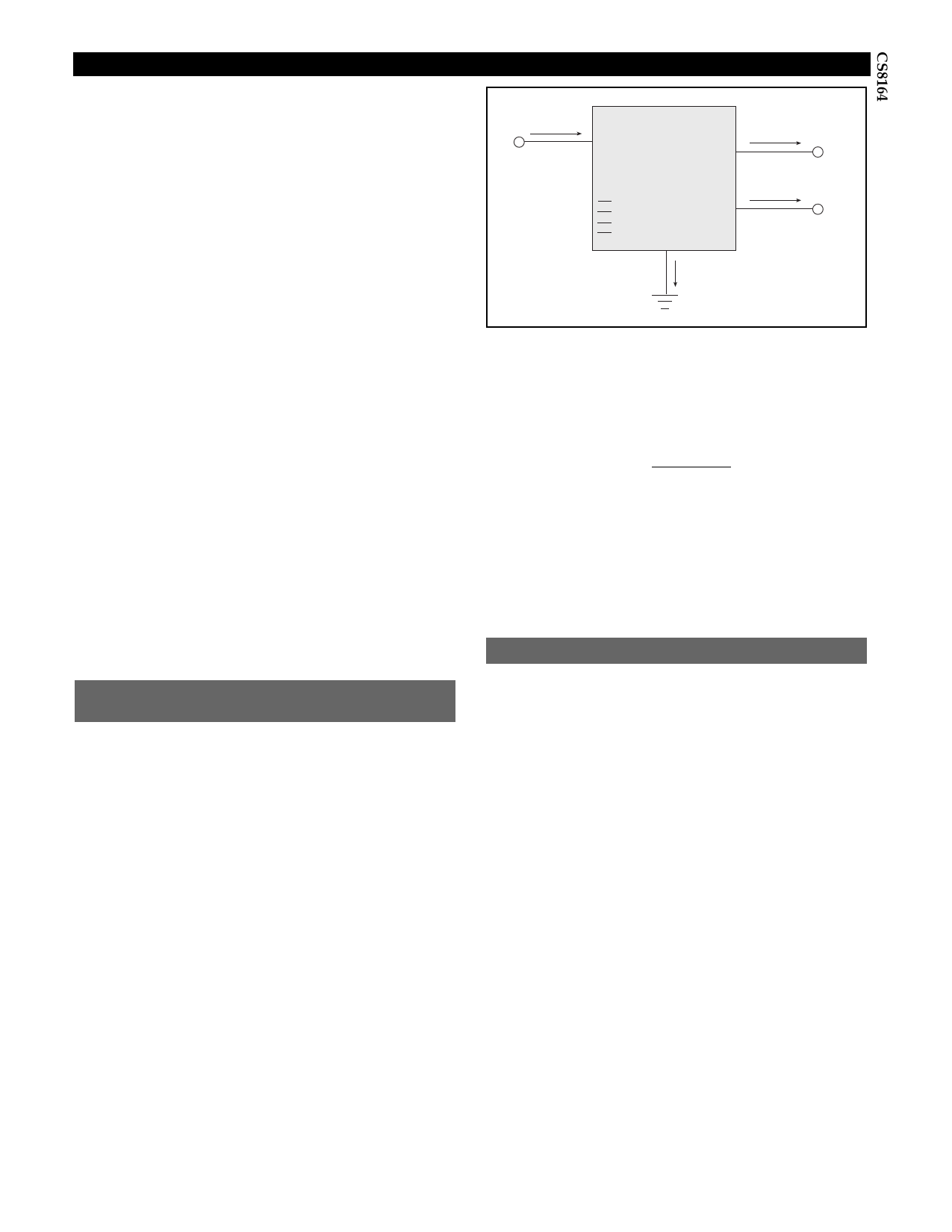

Figure 1: Dual output regulator with key performance parameters

labeled.

Once the value of PD(max) is known, the maximum permis-

sible value of RQJA can be calculated:

RQJA =

150¡C - TA

PD

(2)

The value of RQJA can then be compared with those in the

package section of the data sheet. Those packages with

RQJA's less than the calculated value in equation 2 will keep

the die temperature below 150¡C.

In some cases, none of the packages will be sufficient to

dissipate the heat generated by the IC, and an external

heatsink will be required.

Heat Sinks

Calculating Power Dissipation

in a Dual Output Linear Regulator

The maximum power dissipation for a dual output regula-

tor (Figure 1) is:

PD(max) = {VIN(max) - VOUT1(min)}IOUT1(max)+

{VIN(max) - VOUT2(min)}IOUT2(max)+VIN(max)IQ

(1)

where:

VIN(max) is the maximum input voltage,

VOUT1(min) is the minimum output voltage from VOUT1,

VOUT2(min) is the minimum output voltage from VOUT2,

IOUT1(max) is the maximum output current for the applica-

tion,

IOUT2(max) is the maximum output current for the applica-

tion, and

IQ is the quiescent current the regulator consumes at

IOUT(max).

A heat sink effectively increases the surface area of the

package to improve the flow of heat away from the IC and

into the surrounding air.

Each material in the heat flow path between the IC and the

outside environment will have a thermal resistance. Like

series electrical resistances, these resistances are summed

to determine the value of RQJA:

RQJA = RQJC + RQCS + RQSA

(3)

where:

RQJC = the junction-to-case thermal resistance,

RQCS = the case-to-heatsink thermal resistance, and

RQSA = the heatsink-to-ambient thermal resistance.

RQJC appears in the package section of the data sheet. Like

RQJA, it too is a function of package type. RQCS and RQSA

are functions of the package type, heatsink and the inter-

face between them. These values appear in heat sink data

sheets of heat sink manufacturers.

7