C7460 데이터 시트보기 (PDF) - Hamamatsu Photonics

부품명

상세내역

일치하는 목록

C7460 Datasheet PDF : 8 Pages

| |||

Real-Time Plasma Monitoring

BACKGROUND

Up to 60 percent of the time that a piece of semi-

conductor manufacturing equipment spends in oper-

ation is generally for non productive jobs like plas-

ma cleanup, chamber stabilization (seasoning) and

system diagnosis. Typical approaches for reducing

down-time and repetitive processes like these are to

utilize Advanced Process Control (APC) and Sensor

Based Process Control (SBPC) technologies with

factory LAN services. The MPM allows you to gain

full control over processes using information provi-

ded by the MPM regarding plasma spectra, etching

end-point detection status, plasma fault status, etc.

The MPM opens the possibility of significantly in-

creasing the efficiency of manufacturing equipment.

PLASMASPEUTCTTHEINRGING

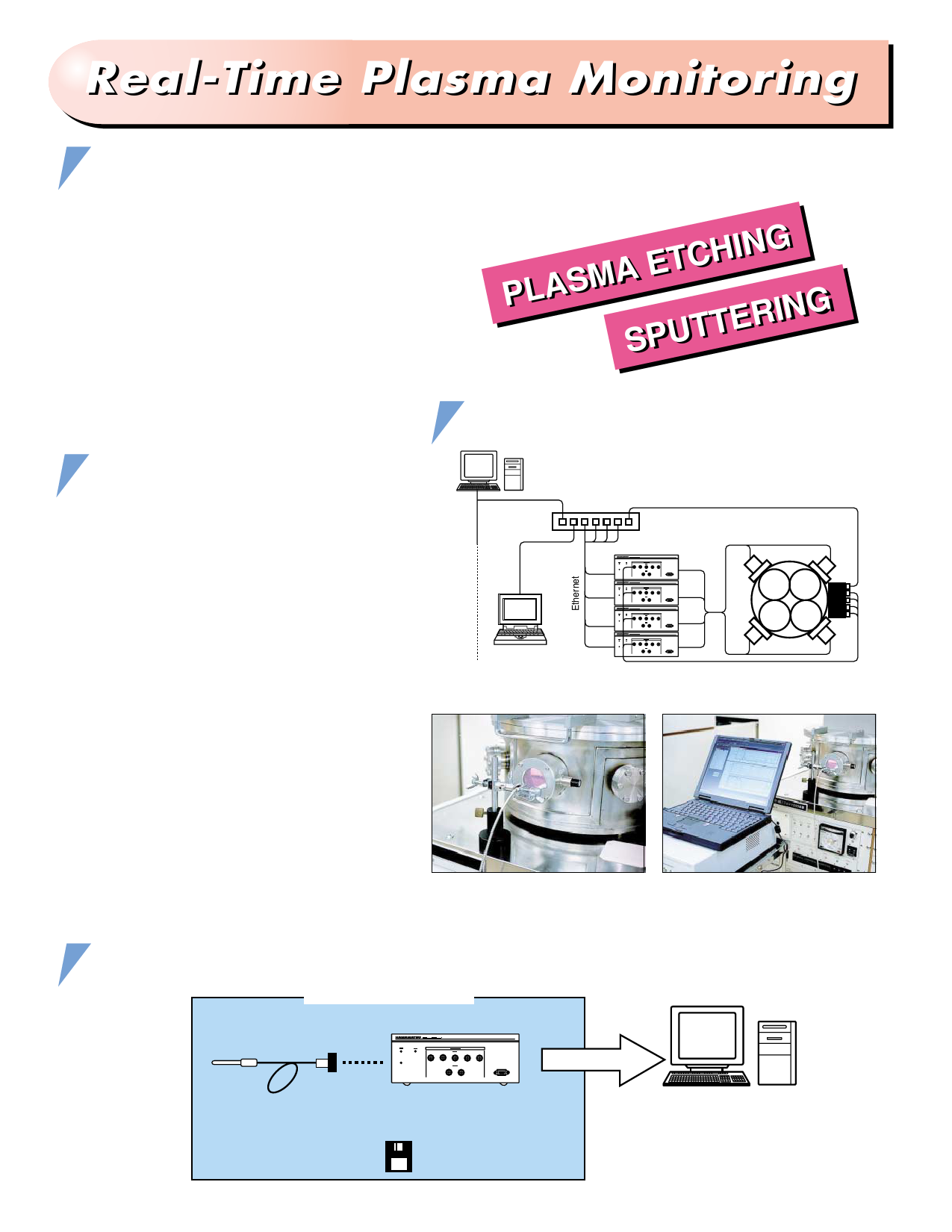

CONFIGURATION OF APC WITH MPM (EXAMPLE)

FEATURES

q Highly Accurate and Reliable

The MPM employs a high-resolution compact spec-

trograph and a highly sensitive detector which diag-

nose plasma with elevated levels of precision.

Along with these superior photometric characteris-

tics, the MPM is compact, sturdy and offers the high

standards of reliability that are required in a manu-

facturing environment.

q Easy to Operate

The MPM is equipped with a sturdy fiber optic bun-

dle, which can conveniently be combined with the

plasma chamber. Due to this, and due to its easy-to

use software, the MPM is easy to setup and operate.

q Intelligent Sensor System

The MPM is not just a spectrograph. It also contains in-

ternal data processing capabilities which allow to ex-

tract and compress the relevant infomation from the

data.

q Easy Fab Integration

The MPM is equipped with several interfaces in-

cluding Ethernet and a TCP/IP protocol stack. To-

gether with its very verstile software framework this

allows the easy integration into existing fab IT infra-

structure.

STANDARD CONFIGURATION

Ethernet

MPM Standard Configuration

HUB

Ethernet

MPM

POWER

1

2

3

4

5

1

2

C7460

RS-232C

POWER

1

2

3

4

5

1

2

C7460

RS-232C

POWER

1

2

3

4

5

1

2

C7460

RS-232C

POWER

1

2

3

4

5

1

2

C7460

RS-232C

Optical fiber

Script output (end point, plasma fault status, etc)

POWER

1

2

3

4

5

1

2

C7460

RS-232C

Ethernet (TCP/IP)

Fiber input optics

Main unit

U9046 Plasma Process Data Aquisition Software

Windows 98, NT, 2000

Computer

2