HUF76132SK8 데이터 시트보기 (PDF) - Intersil

부품명

상세내역

일치하는 목록

HUF76132SK8 Datasheet PDF : 11 Pages

| |||

HUF76132SK8

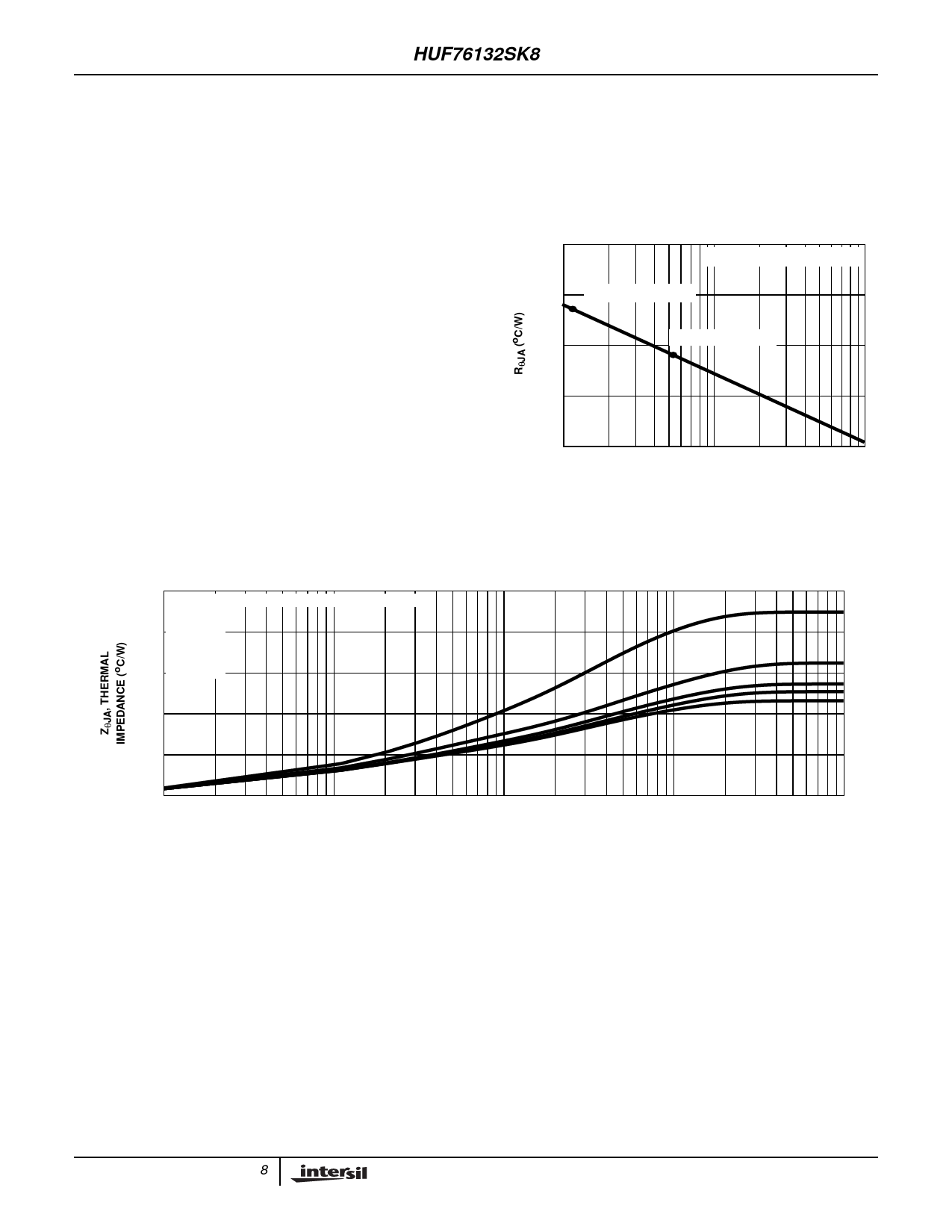

state power with no air flow. This graph provides the

necessary information for calculation of the steady state

junction temperature or power dissipation. Pulse

applications can be evaluated using the Intersil device Spice

thermal model or manually utilizing the normalized maximum

transient thermal impedance curve.

Displayed on the curve are RθJA values listed in the Electrical

Specifications table. The points were chosen to depict the

compromise between the copper board area, the thermal

resistance and ultimately the power dissipation, PDM.

Thermal resistances corresponding to other copper areas can

be obtained from Figure 23 or by calculation using Equation 2.

RθJA is defined as the natural log of the area times a

coefficient added to a constant. The area, in square inches is

the top copper area including the gate and source pads.

RθJA = 83.2 – 23.6 × ln (Area)

(EQ. 2)

The transient thermal impedance (ZθJA) is also effected by

varied top copper board area. Figure 24 shows the effect of

copper pad area on single pulse transient thermal

impedance. Each trace represents a copper pad area in

square inches corresponding to the descending list in the

graph. Spice and SABER thermal models are provided for

each of the listed pad areas.

150

COPPER BOARD AREA - DESCENDING ORDER

0.04 in2

120 0.28 in2

0.52 in2

0.76 in2

90 1.00 in2

Copper pad area has no perceivable effect on transient

thermal impedance for pulse widths less than 100ms. For

pulse widths less than 100ms the transient thermal

impedance is determined by the die and package. Therefore,

CTHERM1 through CTHERM5 and RTHERM1 through

RTHERM5 remain constant for each of the thermal models. A

listing of the model component values is available in Table 1.

240

ln RθJA = 83.2 - 23.6* (AREA)

200

189oC/W - 0.0115in2

160

152oC/W - 0.054in2

120

80

0.01

0.1

1.0

AREA, TOP COPPER AREA (in2)

FIGURE 23. THERMAL RESISTANCE vs MOUNTING PAD AREA

60

30

0

10-1

100

101

102

103

t, RECTANGULAR PULSE DURATION (s)

FIGURE 24. THERMAL IMPEDANCE vs MOUNTING PAD AREA

8