LTC1522CMS8 데이터 시트보기 (PDF) - Linear Technology

부품명

상세내역

일치하는 목록

LTC1522CMS8 Datasheet PDF : 8 Pages

| |||

LTC1522

APPLICATIONS INFORMATION

A ceramic capacitor is recommended for the flying capaci-

tor with a value in the range of 0.1µF to 0.22µF. Note that

a large value flying cap (> 0.22µF) will increase output

ripple unless COUT is also increased. For very low load

applications, CFLY may be reduced to 0.01µF to 0.047µF.

This will reduce output ripple at the expense of efficiency

and maximum output current.

Output Ripple

Normal LTC1522 operation produces voltage ripple on the

VOUT pin. Output voltage ripple is required for the LTC1522

to regulate. Low frequency ripple exists due to the hyster-

esis in the sense comparator and propagation delays in the

charge pump enable/disable circuits. High frequency ripple

is also present mainly due to ESR (Equivalent Series

Resistance) in the output capacitor. Typical output ripple

under maximum load is 50mVP-P with a low ESR 10µF

output capacitor.

The magnitude of the ripple voltage depends on several

factors. High input voltages (VIN > 3.3V) increase the output

ripple since more charge is delivered to COUT per clock

cycle. A large flying capacitor (> 0.22µF) also increases

ripple for the same reason. Large output current load and/

or a small output capacitor (< 10µF) results in higher ripple

due to higher output voltage dV/dt. High ESR capacitors

(ESR > 0.5Ω) on the output pin cause high frequency

voltage spikes on VOUT with every clock cycle.

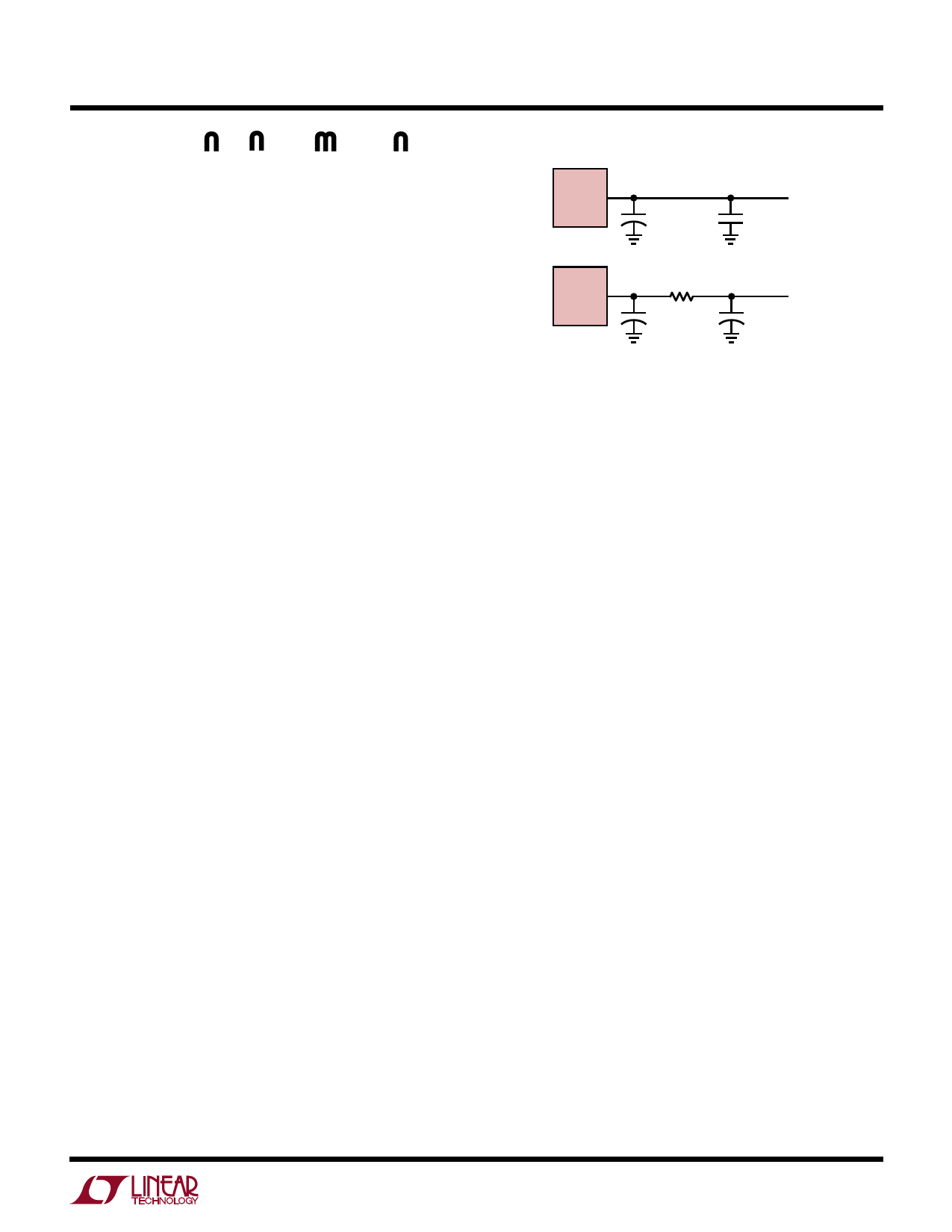

There are several ways to reduce the output voltage ripple.

A larger COUT capacitor (22µF or greater) will reduce both

the low and high frequency ripple due to the lower COUT

charging and discharging dV/dt and the lower ESR typi-

cally found with higher value (larger case size) capacitors.

A low ESR ceramic output capacitor will minimize the high

frequency ripple, but will not reduce the low frequency

ripple unless a high capacitance value is chosen. A reason-

able compromise is to use a 10µF to 22µF tantalum

capacitor in parallel with a 1µF to 3.3µF ceramic capacitor

on VOUT to reduce both the low and high frequency ripple.

An RC filter may also be used to reduce high frequency

voltage spikes (see Figure 1).

LTC1522

3

VOUT +

15µF

TANTALUM

VOUT

5V

1µF

CERAMIC

LTC1522

3

VOUT +

3.9Ω

10µF

+

TANTALUM

VOUT

5V

10µF

TANTALUM

1522 F01

Figure 1. Output Ripple Reduction Techniques

In low load or high VIN applications, smaller values for

CFLY may be used to reduce output ripple. A smaller flying

capacitor (0.01µF to 0.047µF) delivers less charge per

clock cycle to the output capacitor resulting in lower

output ripple. However, the smaller value flying caps also

reduce the maximum IOUT capability as well as efficiency.

Inrush Currents

During normal operation, VIN will experience current tran-

sients in the 50mA to 100mA range whenever the charge

pump is enabled. During start-up, these inrush currents

may approach 250mA. For this reason, it is important to

minimize the source resistance between the input supply

and the VIN pin. Too much source resistance may result in

regulation problems or even prevent start-up.

Ultralow Quiescent Current (IQ = 2.1µA)

Regulated Supply

The LTC1522 contains an internal resistor divider (refer to

the Block Diagram) that draws only 1µA (typ) from VOUT.

During no-load conditions, the internal load causes a

droop rate of only 100mV per second on VOUT with

COUT = 10µF. Applying a 2Hz to 100Hz, 95% to 98% duty

cycle signal to the SHDN pin ensures that the circuit of

Figure 2 comes out of shutdown frequently enough to

maintain regulation during no-load or low-load condi-

tions. Since the part spends nearly all of its time in

shutdown, the no-load quiescent current (see Figure 3a) is

approximately equal to (VOUT)(1µA)/(VIN)(Efficiency).

5